Push Back Racking vs. Drive-In: Which Is Right for You?

- Dan Cook

- Oct 18

- 2 min read

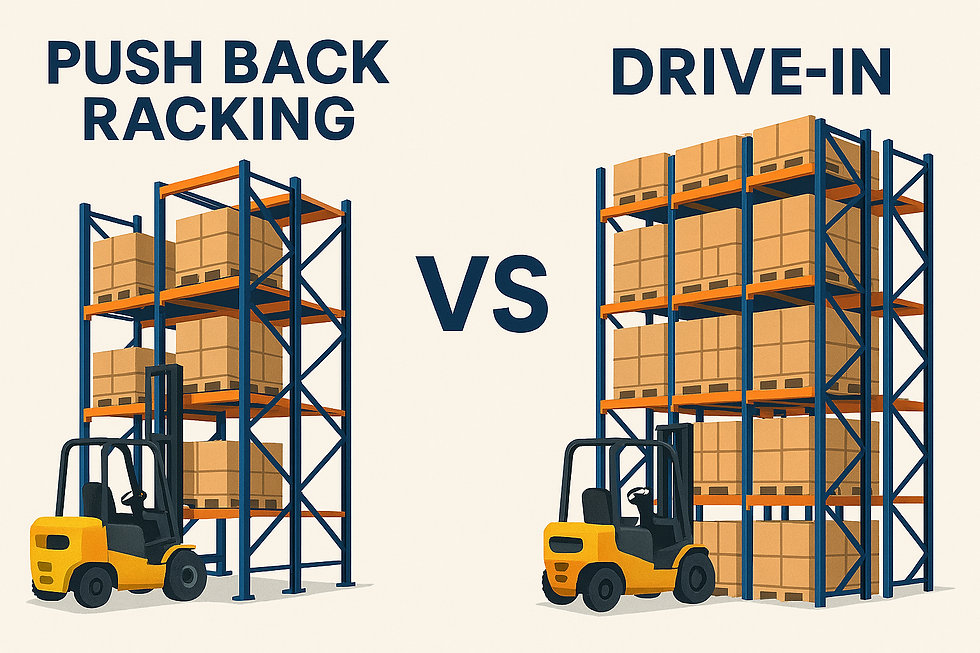

When it comes to optimizing warehouse storage, choosing the right racking system can make a significant impact on your operational efficiency, space utilization, and bottom line. Two popular high-density storage solutions—Push Back Racking and Drive-In Racking—offer distinct advantages depending on your inventory profile and operational needs. So, which one is right for your facility?

Let’s break it down.

Push Back Racking: Efficiency Meets Selectivity

Overview:Push Back Racking is a dynamic storage system where pallets are loaded onto nested carts that roll on inclined rails. Each new pallet pushes the previous one back, and when a pallet is removed, the others roll forward automatically.

Best For:

Facilities with multiple SKUs.

Operations requiring Last-In, First-Out (LIFO) inventory rotation.

Warehouses aiming for high selectivity and dense storage.

Pros:

High Storage Density: Utilizes depth to store multiple pallets per lane.

Better Selectivity: Each lane can store a different SKU.

Faster Loading/Unloading: No need to drive into the rack structure.

Cons:

Higher Initial Cost: More complex design and components.

Limited Depth: Typically up to 6 pallets deep.

Drive-In Racking: Maximum Density for Uniform Inventory

Overview:Drive-In Racking allows forklifts to drive directly into the rack structure to place or retrieve pallets. It’s ideal for storing large quantities of the same product.

Best For:

Bulk storage of homogeneous products.

Operations using Last-In, First-Out (LIFO) inventory rotation.

Facilities with limited space and high-volume storage needs.

Pros:

Maximum Space Utilization: Eliminates aisles between racks.

Cost-Effective for Bulk Storage: Simple design with fewer moving parts.

Cons:

Low Selectivity: One SKU per lane.

Slower Access: Forklifts must drive into the rack, increasing handling time.

Higher Risk of Damage: More forklift interaction with the rack structure.

Key Considerations When Choosing

SKU Variety:

Multiple SKUs? Go with Push Back.

Single SKU in bulk? Drive-In might be better.

Inventory Rotation Needs:

Both systems operate on LIFO principles.

For FIFO, consider alternatives like Pallet Flow Racking.

Space Constraints:

Drive-In offers greater density, ideal for tight spaces.

Push Back balances density with better accessibility.

Budget:

Drive-In is generally less expensive upfront.

Push Back may offer better ROI through faster operations and reduced damage.

Final Thoughts

Choosing between Push Back and Drive-In Racking isn’t a one-size-fits-all decision. It depends on your product mix, throughput requirements, and space constraints. At Pet Brands Platform, we specialize in helping businesses like yours make informed decisions that drive efficiency and profitability.